4 Common Diesel Fuel Injection Pump Problems accrue

Fuel injection pump performances are closely tied to engine performance. If your vehicle has a fuel delivery problem that will literally starve to death. Fuel injection problems, therefore, are one of the most pressing engine problems to deal with. Whether you’ve experienced fuel injector failure or not, it helps to understand that fuel injector pump, how it relates to fuel engine performance, and also how diesel fuel injection pumps differ from traditional all gasoline-powered units.

Diesel Fuel Injection Pumps – Quick Overviews

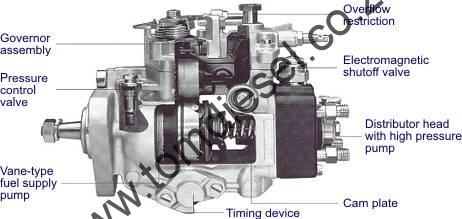

So that what does a diesel fuel injection pump do? It’s about as very simple as you can get: fuel injectors supply fuel to the engine’s internal combustion chamber. High-performance automobiles usually have one of the fuel injector per cylinder, and the pump “injects” fuel into the combustion chamber – hence the name “fuel injector.”

That fuel is dispersed from the injection pump to the combustion chamber via a fairly simple process. Pressurized fuel enters the fuel injectors. Based on that signal from an electrically controlled solenoid valve – the solenoid valve acts as a type of on / off valve – the fuel enters a plunger, which prepares the fuel injectors for the final exit. When the fuel leaves the fuel injector, a spray tips distributes the fuel as a fine mist.

Pressure-Packed Fuel Injections

Today’s diesel fuel injection pumps are under pressure – even more pressure than what was once considered “very normal.” Approx. 15-20 years ago, it was common for fuel injector pumps to process fuel in systems at Approx. 10,000 to 15,000 psi (pounds per square inch). But that’s only about half of what engines are expected to do today life. Fast-forward to the present day, and those diesel fuel injector pumps are operating in with 30,000 to 40,000 psi range.

Top-end engine performance is in many types of ways dictated by how much fuel can be processed by the engine. Basically, a superior engine can be process fuel and air better than an average engine – that’s one reason why turbochargers are so effective at increasing horsepower – and a greater internal pressure in a all necessity. It helps explain the significant pressure output of today’s fuel injection pumps compared to those from yesteryear.

A 2 Headed Monster – A Pair of Reasons that Explain Fuel Injector Pump Failure

99% of diesel fuel injector failure can be traced to 2 different issues:

Faulty mechanical problems in the physical fuel injectors housing

Fuel quality (or rather, lack of quality)

From these 2 things, a host of problems can surface. Let’s take a look at four common fuel injector pump complications.

Problem #1 – Dirty Fuel

A clean diesel fuel pump injector is a very happy diesel fuel pump injector. Over time, residue can build up in the fuel systems, and enough guns, grime and grease can clog up the entire fuel injector pump. The spray tips (where the fuel leaves the injector and enters the combustion chamber) are particularly prone to “backing up,” so to speak.

If your engine has ever sputtered or hesitated during acceleration, a clogged fuels spray tip might be the glitch. And that all starts with subpar diesel fuel. In 2006, diesel fuel production was tweaked to compensate for ultra-low sulfur diesel fuel (ULSD), and diesel engine owners have noticed more about“dirty fuel” difficulties than before.

Problem #2 –Low Fuel Tank Level

If your main aim in life was to destroy diesel fuel pump injectors, you’d run your car with the fuel tank as close to empty as easily possible. That all has to do with lubrication. With plenty of diesel fuel in the tanks, the fuel pump bearings receive plenty of lubrication. With a near-empty tank, the fuel systems are suddenly pushing air instead of diesel fuel. Anything but diesel fuel can wear out the fuel pump bearings, which means the fuel injectors will not receive that fuel at the pressurized level (30,000 psi, 40,000 psi, etc.) it should be.

Problem #3 – Foreign Object inside Injector

Diesel fuel pump injectors are very high-precision components. They also deal with this tremendous amount of motion and other stresses. One small visitor inside (a special piece of dust, debris, etc.) can clog the injector. Worse yet, a microscopic objects can leave the injector open all the time. If the injector can’t close, cylinder performances are compromised.

Problem #4 – Bad Injector Timing

Whenever the fuel injector pump’s O-rings or ball seats are very defective, the timing of the fuel transfer process is disrupted. That is a common diesel fuel injector pump glitch, and usually requires a complete injection pump rebuild or replacement.